Industry 5.0 represents a significant evolution compared to previous industrial phases, focusing on the increasingly close integration between man and machine and, in this context, Augmented Reality (AR) plays a fundamental role in optimizing processes production and improve collaboration between human operators and automated systems.

Characteristics of Industry 5.0

The European Commission in the document Industry 5.0 – Towards a sustainable, human-centric and resilient European industry, underlines the three fundamental characteristics of this new production model:

- Sustainable Industry: industry 5.0 is committed to sustainability, seeking to reduce environmental impact through more efficient and eco-sustainable practices. This may include optimizing energy consumption, reducing raw material waste, implementing cleaner production processes and partnering with suppliers who uphold the same values and practices;

- Human-centered industry: despite advanced automation, humans remain at the center of industrial operations and technology is seen as a tool to improve human work.

This new direction ensures that the implementation of the technology respects the fundamental rights of workers. In this way, we promote a vision in which technology acts as a support and enrichment of the work experience, without compromising the essential values of the person; - Resilience: in the context of Industry 5.0, resilience emerges as a crucial element to ensure the operational continuity of companies in the face of unexpected events, such as economic crises, natural disasters or disruptions in the supply chain. The adoption of new innovative technologies, therefore, plays a fundamental role, acting as a powerful ally in strengthening companies’ ability to adapt and respond promptly to emerging challenges.

What is Augmented Reality?

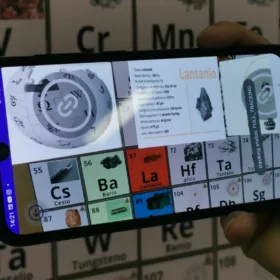

Augmented Reality is based on the use of technological devices, such as Smart Glasses, tablets or smartphones, and software solutions that superimpose digital information on the surrounding physical world. This means that operators working in any field can see data, information, processes or instructions directly in their field of vision as they work.

Augmented Reality can be of great help in Industry 5.0 in several ways:

- Production assistance: operators can receive real-time instructions during production, reducing errors and increasing efficiency;

- Sustainability and cost reduction: the sustainable aspect is central to Industry 5.0, and remote collaboration helps reduce travel, helping the environment and bringing significant economic savings;

- Maintenance and repair: AR can be used to simplify maintenance operations by allowing operators to view detailed instructions or work processes directly on the equipment being repaired;

- Remote collaboration: AR allows experts or supervisors to provide support remotely.

Field workers can share their point of view across devices, allowing distant experts to observe what they see and provide assistance in real time; - Training: Augmented Reality can be used for staff training, allowing operators to learn through experience, and be guided by a remote expert.

B View and B Step are Brochesia‘s Augmented Reality solutions designed to help you in every phase of your company’s production process.

Contact us for more information and to take advantage of a free trial!