The implementation of augmented reality in the chemical-pharmaceutical industry is leading to a significant change in remote and sustainable collaboration and optimization of operational activities.

COMBER Process Technology S.r.l., a leader in the process machinery industry, has addressed this challenge by focusing on improving communication between field personnel and the engineering department. Founded in 1960, the company has focused on the production of filters, dryers and filter-dryers, maintaining a high standard of safety and quality of work.

Integrated solutions to improve communication and safety

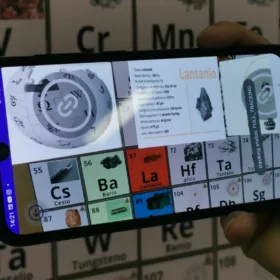

With the strategic support of our partner Fastbrain Engineering Srl, a system integrator and technology consultant for companies, COMBER found an effective solution for communication and safety needs through the adoption of our augmented reality software B View.

This solution addressed COMBER’s initial need to provide a tool for After-Sales department technicians to communicate in real time with the technical department, during interventions at the plants.

This allowed for improved transmission of critical information even in ATEX-rated environments, thanks to the use of B View software on RealWear Navigator Z1 smart glasses, which allow field technicians to operate hands-free and safely.

Brochesia solutions offered by Fastbrain Engineering, also provided remote support during production and assembly activities, eliminating the need to use devices such as smartphones or cameras.

An additional benefit was offered to COMBER’s customers, who were able to remotely participate in final machine testing before delivery, increasing transparency and collaboration between the company and its customers.

The benefits of augmented reality in the chemical-pharmaceutical industry

COMBER’s experience in using our augmented reality solutions through its partnership with Fastbrain Engineering has demonstrated numerous benefits, including the flexibility and speed of use of the B View software, with advanced augmented reality capabilities, and the ability to control the RealWear Navigator Z1 entirely by voice, thanks to intuitive and responsive controls that ensure maximum efficiency even in ATEX zones.

In addition, the support provided during the training period facilitated rapid and effective adoption of the new technologies within the company.

Innovative technologies to improve competitiveness and efficiency

Considering the positive results so far, COMBER recommends that other companies in the industry adopt the Brochesia augmented reality solutions proposed by Fastbrain Engineering.

These technologies enable companies to remain competitive by improving operational efficiency, collaboration, and quality of service to customers worldwide.

The case of COMBER clearly illustrates the transformative role of augmented reality in optimizing remote collaboration and increasing safety and efficiency in the chemical-pharmaceutical industry.

Through its strategic partnership with Fastbrain Engineering and the use of Brochesia solutions, COMBER has been able to overcome complex challenges, demonstrating the tangible value of new technologies in the modern industrial environment and establishing itself as an innovator in the chemical-pharmaceutical market.

Contact us to request a demo and bring augmented reality to your company.