Industry 4.0 has shown the automation sector that resources must be used in a prudent way. This difficult period has shown above all to this sector that there is no going back, but innovative digital business models must be developed to recover productivity.

If there is a positive aspect to be found in recent months, in fact, it is precisely the awareness that technologies are able to maintain many economic activities despite the forced closure of factories and offices. The lockdown has prompted many companies in the automotive sector to release the reluctant sentiment around 4.0 technologies and massively adopt digital solutions to continue operating.

Despite the breaking moment, digital is able to give a decisive push to allow companies in the automation sector to put the current recession behind them as soon as possible. It will be possible to do this by developing new services and business models to recover productivity.

To do so, however, radical changes are needed. An example is given by smart working, widely used from March onwards. “With the persistence of the difficulties of moving (for questions not only of limitations, but also of cost), and with greater awareness of the advantages of remote work, the next goal to be achieved is to manage remotely even articulated meetings and with actors external to the “organization”, analysts of the School of Management of the Politecnico di Milano write, with reference to complex project meetings, commercial negotiations, reviews and work progress tests.

On the positive side, despite the economic situation, sentiment towards industry 4.0 remains marked by optimism, strengthened by the consideration that the emergency has accelerated the digital transformation.

In a time when resources are not abundant, it is essential to optimize efforts. Various researches have highlighted how the management of innovation 4.0 projects is still a gap for many companies, especially Italian ones, which carry out scattered initiatives, without a roadmap, a strategic program or coordination.

The Covid-19 pandemic occurs at a time when remote support, 5G and innovation in software development really come into play. The lockdown itself made it possible to test network services, even if they were used far more heavily than in the pre-Covid era.

At the basis of these digital transformations, cyber security therefore becomes a key element. The growing popularity of cloud applications and services requires careful consideration of the integrity mechanisms of downloading and installing authentic software and firmware, the granting of protected software licenses and the defense of the entire digital heritage of the company, wherever it is widespread.

In the automotive sector too, the pandemic has proven to be a formidable accelerator of digital transformation. This is demonstrated by the majority of companies in the sector, from the largest to the smallest, which in the lockdown period to allow dealers to stay in touch with customers, thus offering them information and assistance, innovations that – even after reopening – will transform profoundly the consumer journey.

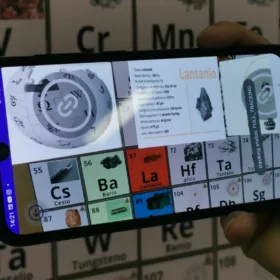

Through the Brochesia B View software solution, companies belonging to the automation sector are thus able to provide efficient and effective support in the maintenance, development, design and production of products and services in numerous locations around the world.

Brochesia solutions are not limited to the support provided through Smart Glasses: the software is compatible with any Android mobile device (tablet and smartphone), so as to give anyone the opportunity to exploit the benefits of Augmented Reality even without the typical advantages wearable devices, thus managing to eliminate long, expensive and exhausting trips.